Meeting the highest standards

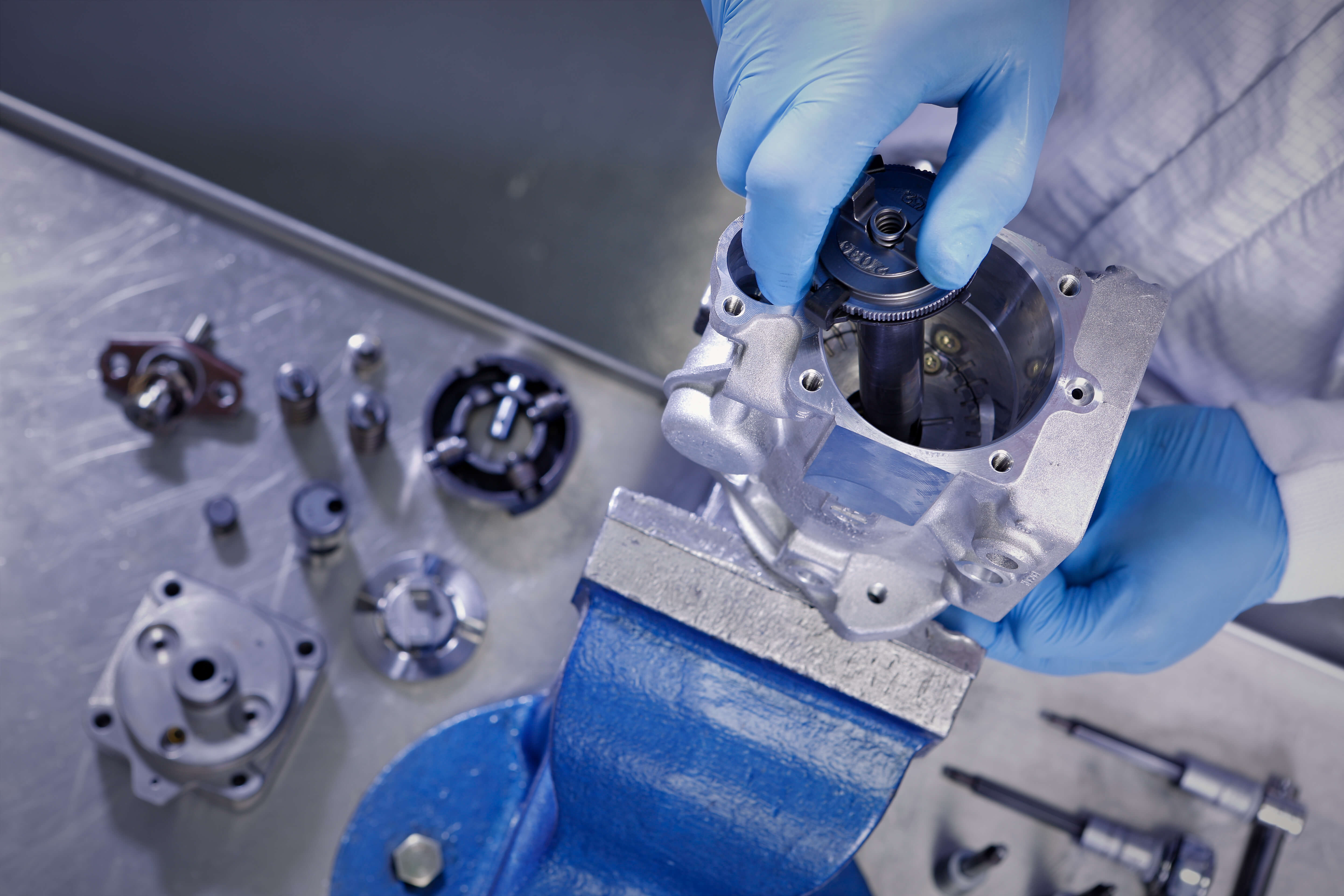

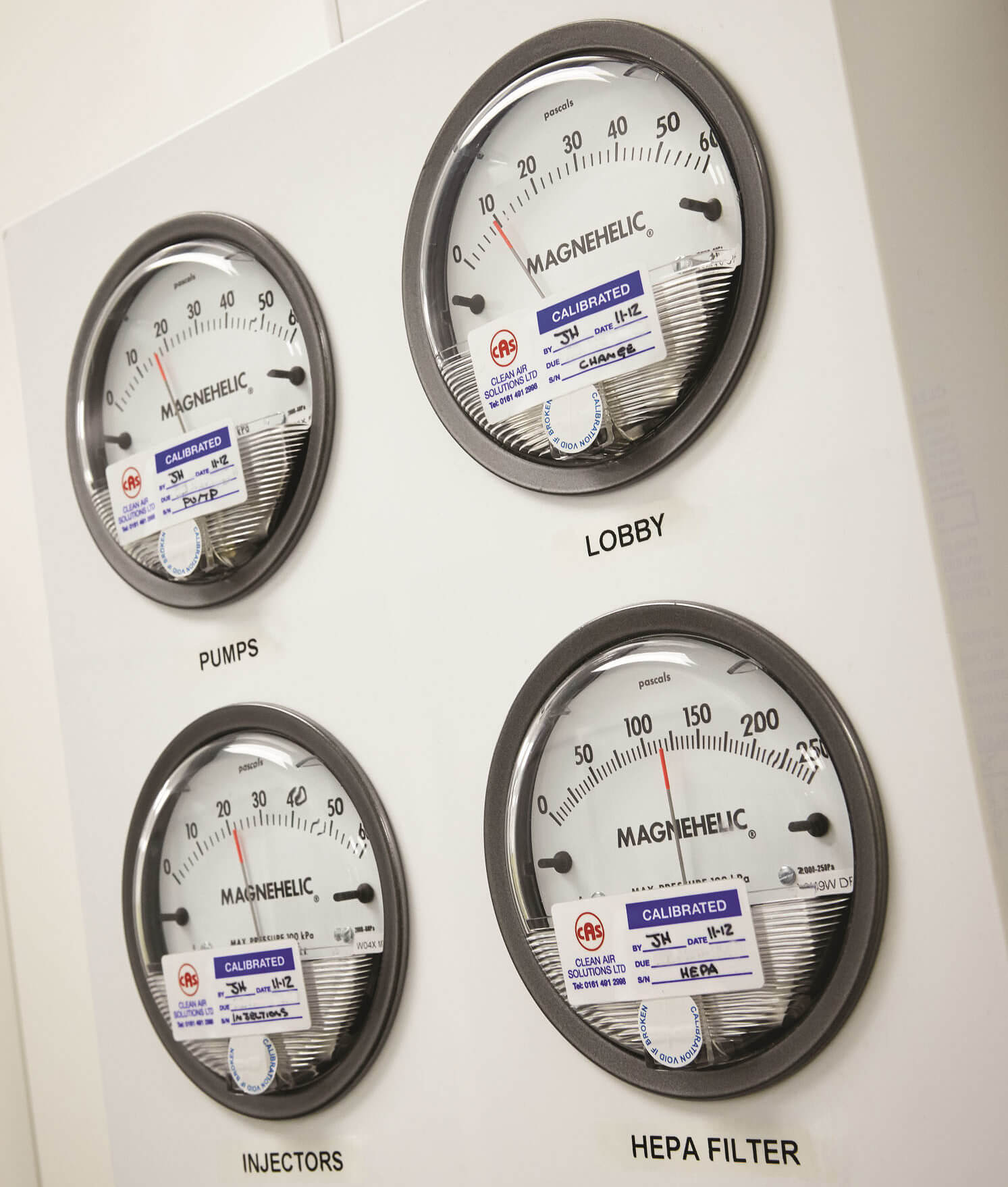

Modern high-pressure diesel parts such as injectors work under extreme hydraulic pressure (up to 3000 bar, almost 45,000 psi) and are manufactured to critically fine tolerances. The particle filtration requirements for fuel contaminants is now at 2 microns, necessitating that the pump and injector parts need to be remanufactured in an environment that meets stringent cleanliness standards. Unique in the UK and one of the most advanced facilities of its type in the world, the Carwood clean room assembly suite ensures OE standards are maintained at the highest level with particle contamination limits down to 0.5 microns.

This is achieved by:

- Personnel entry/exit air locks

- Positive internal air pressure

- Circulation of the total air volume 6 x per hour

- HEPA air filtration systems

- Prevention of contamination through clean protocols

- Product transfer through sealed hatches

The Carwood Diesel Systems Pump and Injector Assembly Rooms are certified to ISO 14644 -1 Class 7.

Meeting the highest standards

Contact Us for More Information on Injector Parts, Clean Rooms or for a Diesel Parts Service

If you have any questions regarding any of our products, services or facilities, please feel free to contact us and we’ll help to answer whatever query’s you may have. Whether you’d like to know how we service diesel injectors and injector parts, or you’d like to understand more about what our Class 7 Assembly Room certification means for you as a customer, we’ll always be more than willing to provide answers and/or advice.

Contact Us for More Information on Injector Parts, Clean Rooms or for a Diesel Parts Service